VoxelDance助力柏林著名医学院Charité打印心血管动脉模型

创建时间:2021-08-05 13:45

上海漫格科技最近与德国代理商DREIGEIST,在Charité 柏林心血管医学成像科学和计算建模研究所的指导下,合作生产了一种完全透明的心血管动脉模型。

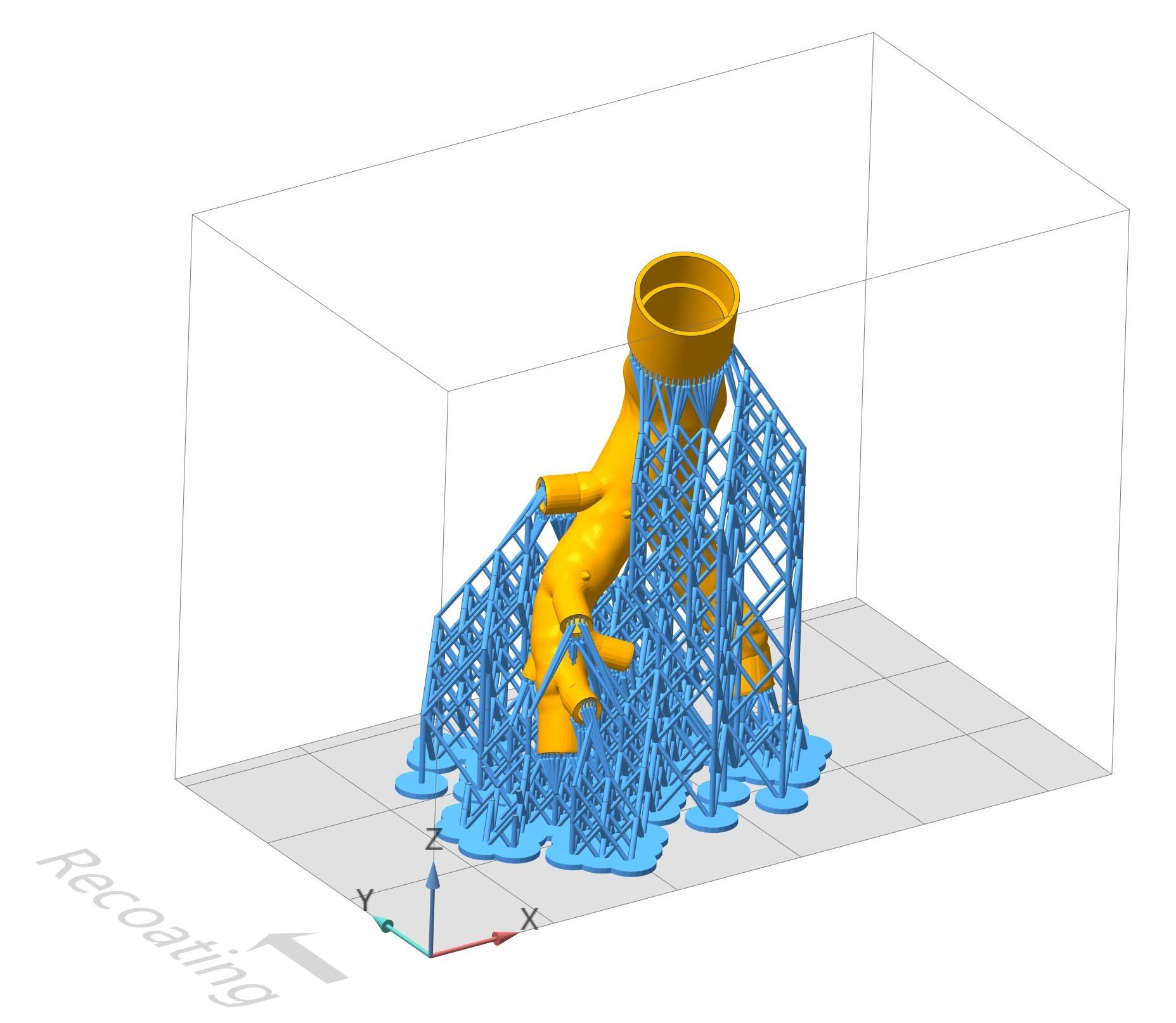

▲心血管动脉模型摆放在VoxelDance Additive软件中,并添加智能支撑结构

柏林Charité研究所的负责人在对各种材料样品进行了光学特性对比后,选择了巴斯夫ForwardAM公司的Ultracur3D®ST45光敏树脂材料,这个材料满足了模型必要的表面质量和透明度。DREIGEIST的应用工程师决定采用UnionTech的最新一代UV LCD打印技术来处理客户对BASF光敏树脂材料的选择。

▲3D打印心血管动脉模型

▲3D打印心血管动脉模型

客户:柏林Charité

材料:巴斯夫Ultracur3D®ST45光敏树脂材料

打印机:UnionTech

数据处理软件:VoxelDance Additive