巴斯夫BASF使用VoxelDance完成SLA鞋楦打印白皮书

图片来自巴斯夫官网

此类鞋楦用于生产和修复鞋子,通常由聚乙烯或硬木制成,其形状和功能已保持数百年不变。 增材制造技术绝对是一个规则改变者:3D打印将交货时间缩短到仅6到12个小时,利用Ultracur3D®RG35可以使后处理,精细成型和抛光变得十分简单,甚至钻孔和攻丝以添加固定销或铰链也很容易且快速.

------巴斯夫鞋模白皮书,来源巴斯夫官网

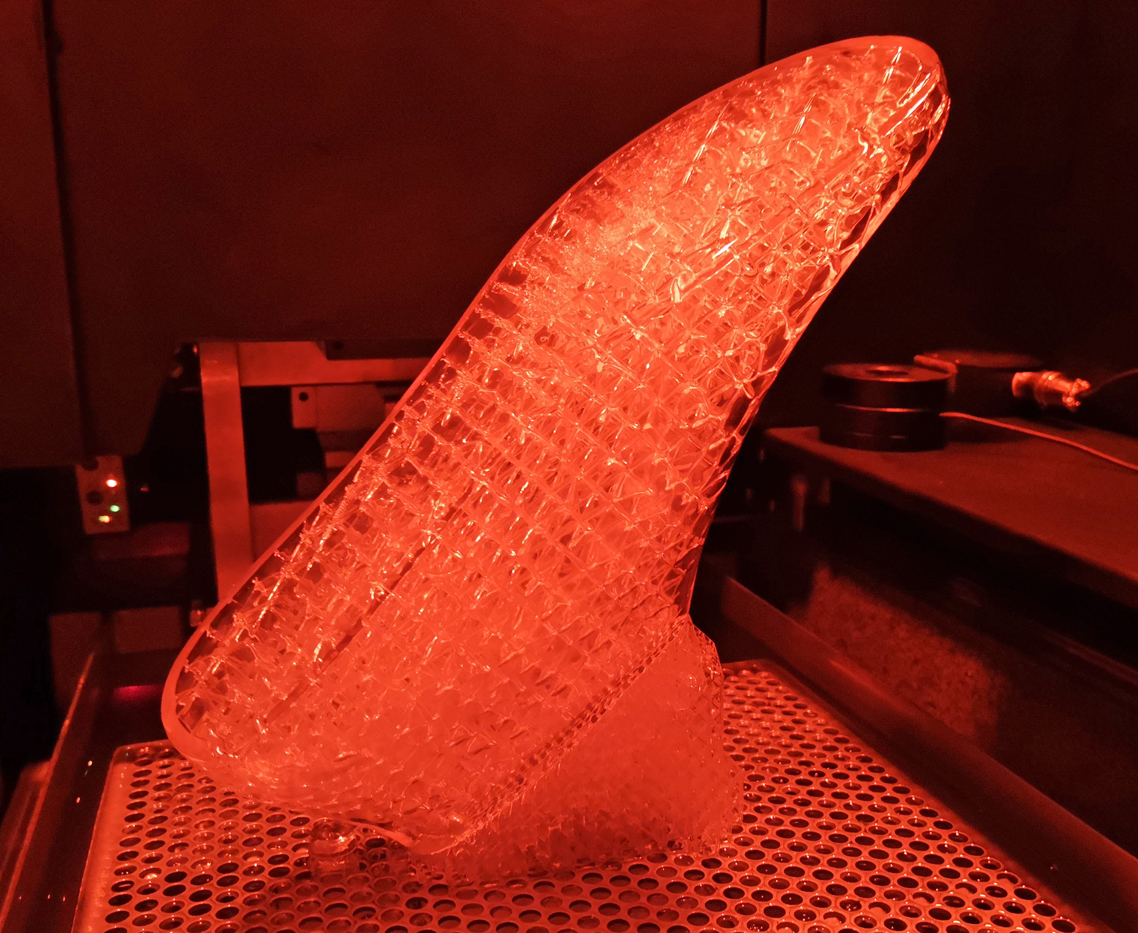

上图带有晶格结构的鞋楦,是由VoxelDance的欧洲代理商DREIGEIST打印。3D打印前数据处理软件:VoxelDance Additive,打印机型号:联泰UNIONTECH PILOT 250HD,材料:巴斯夫BSF RG35。

VoxelDance Additive使整个鞋楦打印在一开始就变得高效和经济。添加晶格结构节约了打印时间和材料,灵活的手动支撑工具能快速添加支撑并保证零件外表面没有支撑附着,提高零件表面精度。自适应切片功能节约了打印支撑的时间,针对切片的Z轴补偿最高精度地还原了整个模型的实际形状。

△ 上图为最终打印成功,带支撑的鞋模打印件

接下来我们就以视频的方式来分享一下的这个鞋楦在VoxelDance Additive中3D打印前数据处理全流程。视频内容主要包括:

-

定义打印平台,选择打印机:UNIONTECH PILOT 250HD。 -

导入扫描零件,并修复零件,使其表面完全光滑。 -

缩放零件,使用预设的BASF材料收缩系数,补偿材料收缩。 -

优化零件方向,避免支撑附着在鞋模的外表面而影响零件精度。 -

给零件抽壳、添加晶格体结构和打孔,减少打印时间和节约打印材料。 -

使用预存的支撑脚本,自动/手动添加智能支撑。 -

使用添加智能支撑工具,在散落的晶格结构底端手动添加支撑。 -

为提高打印成功率,使用添加点支撑工具,为零件最低点添加支撑。 -

切片。使用自适应切片功能,节约打印时间的同时,又能保证零件打印精度。 -

对零件切片进行Z轴补偿,提高零件打印精度。 -

导出切片为CLI格式。

点击下方视频,一睹为快吧!

更多关于巴斯夫鞋模白皮书,可以查看巴斯夫官网介绍:

https://forward-am.com/use-cases-and-whitepapers/mold-and-last/?utm_content=155110697&utm_medium=social&utm_source=linkedin&hss_channel=lcp-5300975&hsa_acc=503692019&hsa_cam=612242883&hsa_grp=177002963&hsa_ad=129539243&hsa_net=linkedin&hsa_ver=3